Flexible, organic, and conductive. Those are adjectives traditionally applied to PEDOT: PSS. Thanks to Dr. Ruben Sarabia-Riquelme and his cohorts at the University of Kentucky Applied Energy Research (UK CAER), and other collaborators at the University of Louisville, KY NSF EPSCoR funds are adding two more adjectives to PEDOT: PSS: spinnable and printable.

Readily available commercially, PEDOT: PSS is a carbon chain with other functional groups that make the chain very conductive. This conductivity is incredibly useful in the context of KY NSF EPSCoR’s Track-1 award, as it looks to advance manufacturing in Kentucky and beyond. As the program examines more efficient ways to build custom flexible electronics, sensors, and devices for manufacturing, PEDOT: PSS could simplify and amplify the way industries about fabrication of those products.

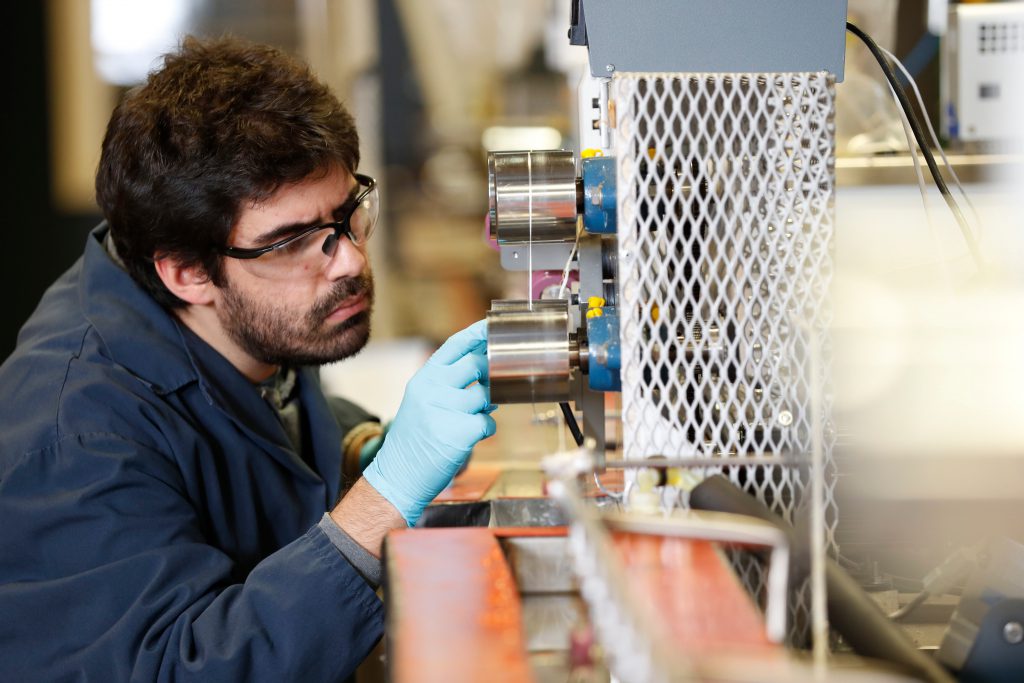

For several years, Dr. Ruben Sarabia-Riquelme under the tutelage of Dr. Matt Weisenberger and their team at UK CAER, has been successful in the solution spinning of Polyacrylonitrile fiber, primarily as a pre-cursor for high-quality carbon fiber. You can learn about the success of this program here: https://caer.uky.edu/caer-ornl-research-partnership-to-turn-coal-into-high-value-carbon-fiber/. This same spinning process, involving wet spinning, is now being recontextualized as a method for spinning spools of PEDOT: PSS fiber with support from KY NSF EPSCoR. As a fiber, the PEDOT: PSS has tremendous potential. A fiber can more easily be 3D-printed, made into supercoils for fabric-like materials, or used as tiny transistors in flexible solar panels, microchips, and sensors.

Traditionally, polymer fibers are insulative and to become conductive must be coated in a conductive material like metal. This makes manufacturing of electronics, transistors, etc. more difficult due to the rigidity of the coating. By fabricating fibers directly using the wet spinning process, the flexible fibers themselves can be the conductive element.

Currently, Dr. Sarabia-Riquelme and his cohorts are working on scaling the fibers from a microgram scale to a gram scale, making them more functional. “A PEDOT fiber would be a building block,” says Sarabia-Riquelme. “The PEDOT fiber could be the interconnection between two electronic components, and because its flexible it could be built into a structure that needs flexibility. For example, it could be in a robotic arm…it could be used in pressure sensing for robot-human interaction.”

His team is testing the fibers as flexible interconnections, and as thermochromic fibers (dyes changing colors), and also micro-heating elements. Because the PEDOT: PSS conducts heat, like metal, the fibers can also be receptive to touch and heat. Although in the distance, one could Imagine the eventual application of these technologies on health care or protective equipment in industry. You can watch Dr. Sarabia-Riquelme’s presentation on his research staring at the 5:05 mark of the nanoCollider presentation below.

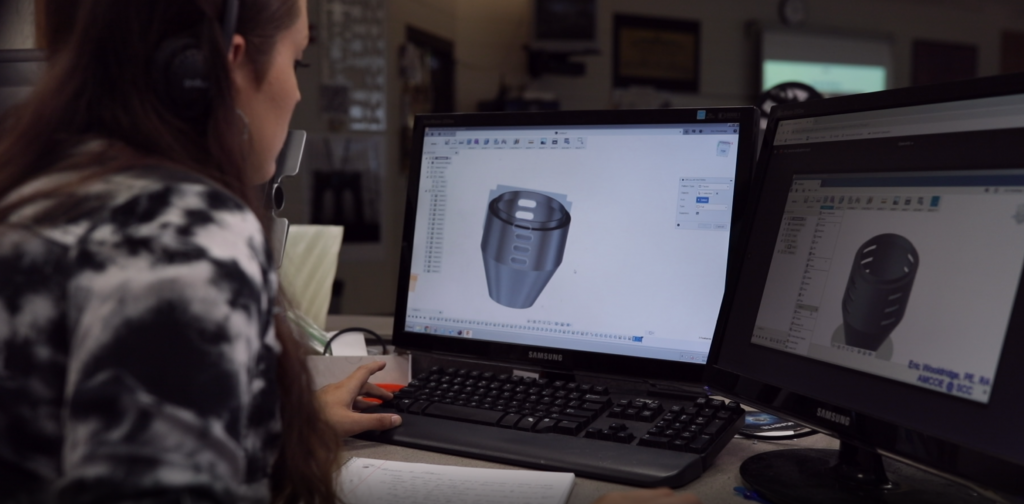

Showcasing the collaborative nature of KY NSF EPSCoR, the PEDOT: SS fibers are distributed from Dr. Sarabia-Riquelme’s lab to other researchers in the program for applicative function. Dr. Cindy Harnett of the University of Louisville takes spools of the conductive PEDOT: PSS and is examining ways to manipulate and tie it into supercoils, making it stronger and more stretchable in the process. Dr. Kunal Kate of UofL looks at ways to use PEDOT:SS in 3D-Printing, his expertise. While there are obstacles currently in optimizing the 3D-printing process, the potential of printed PEDOT could be revolutionary to advanced manufacturing. Dr. Zan Paterson, of UK, and her PhD candidate Paula Alarcon, examine PEDOT in terms of using them as transistors in electronic devices, as well as improving coatings for the fibers to increase durability.

Dr. Sarabia-Riquelme’s work and the PEDOT: PSS collaboration is a perfect example of the power of KY NSF EPSCoR researchers working together towards the goal of enhancing manufacturing. We have the raw materials coming from UK, and then UofL utilizing those materials for applicable function. All made possible through funding through NSF EPSCoR.